MKIII Golf/Jetta Inner and Outer Tie rod DIY.

This

"how to" assumes you have some basic tools, and safety gear. Safety glasses

should be worn at all times when working with tools and automotive fluids.

Always use a hydraulic jack and safety stands when lifting or getting under a

vehicle. If you are unsure on where to safety lift your vehicle, refer to its

owners guide. Steering and Suspension components should never be heated with a

torch, bent, or welded. Replacement parts must be direct matches and should be

torqued to specification. The writer of this how to assumes zero liability

in how to use this guide, or any damages that may come from it to you, your

property, or others and others property. If you are uncertain at any point,

refer to a qualified automotive technician.

This

"how to" assumes you have some basic tools, and safety gear. Safety glasses

should be worn at all times when working with tools and automotive fluids.

Always use a hydraulic jack and safety stands when lifting or getting under a

vehicle. If you are unsure on where to safety lift your vehicle, refer to its

owners guide. Steering and Suspension components should never be heated with a

torch, bent, or welded. Replacement parts must be direct matches and should be

torqued to specification. The writer of this how to assumes zero liability

in how to use this guide, or any damages that may come from it to you, your

property, or others and others property. If you are uncertain at any point,

refer to a qualified automotive technician.

Inner and outer tie rods are major players in the steering

system. The connect the left and right directional forces of the steering

rack, out to the knuckles and in turn the wheels and tires. Constant

stress, impact and wear eventually cause loose steering, tire wear, drifting and

pulling. Having a vehicle that is lowered also causes some abnormal stress

on these components, and can in turn shorten life. OEM parts on a stock

MKIII should last 80-100k miles.

For a quick primer on steering systems visit -

How Stuff Works.

Never add any type of grease to a sealed joint.

Some aftermarket types may have a grease fitting, if so they are not the

original ones and may be greased. If the boot is torn, I'd just install a

new outer joint, I don't think you can get new boots. The reason why you

should not just shoot grease, or WD-40 into them is because they have a plastic

"socket" that the ball sits in. Adding a petroleum based grease will only

cause the joint to fall apart sooner.

How can I tell its bad? Well, testing for a bad tie

rod is easy.

1 - Noise, if the joint, squeaks or squawks on turns.

2 - The boot is torn open

3 - When you grab the tire/wheel at 9 and 3 o' clock and move it back and forth

(see diagram) and the tie rods have free play...

4 - There is a clunking sound when you have the car parked, and you turn the

steering wheel side to side.

5 - VIDEO LINK

see this by seeing this comparison of two types of inner tie rods.

The MKIII model line has two types of steering racks.

Most 2.0 cars have a TRW design. This rack is on the "base" suspension,

and is seen by having a smooth painted finished. VR6 or "plus" suspension

cars have a ZF design, these cars have an-all aluminum rack that has a "waffle

grid" design. The tie rods for the two types of racks work the same way,

but are not the same. Make sure to check your rack design before you

order parts. There are a few cars out there (from swaps and so on)

with mixed parts. This DIY shows a 2.0 car with a TRW base suspension

rack.

The tie rods (inner) are the same for left/right - the

outers are not, and are stamped with an L or R. L is the drivers side, R

is the passenger. Make sure not to mix them up when installing them.

I prefer to always replace inner and outer joints as sets. Its almost

silly not to. If you replace a bad outer joint, how far away is the inner

joint from failing? Right, you don't know, and if your paying for a proper

alignment, you'll wind up doing the same job twice. So, I prefer to

replace them as sets. And what goes for the left, goes for the right.

This is not NASCAR, your car makes just as many left turns as right ones - so

replace "all four tie rods" and say hello to like new steering.

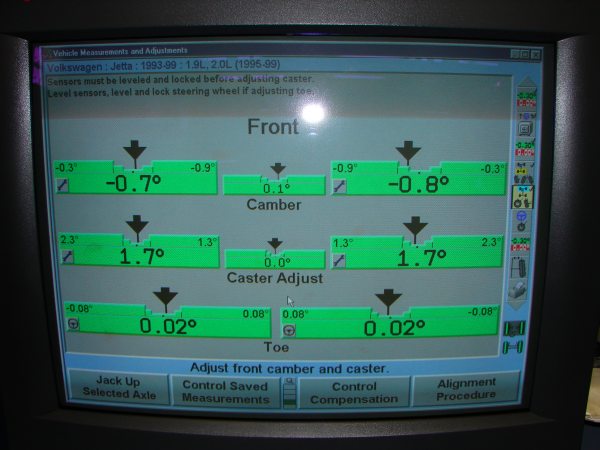

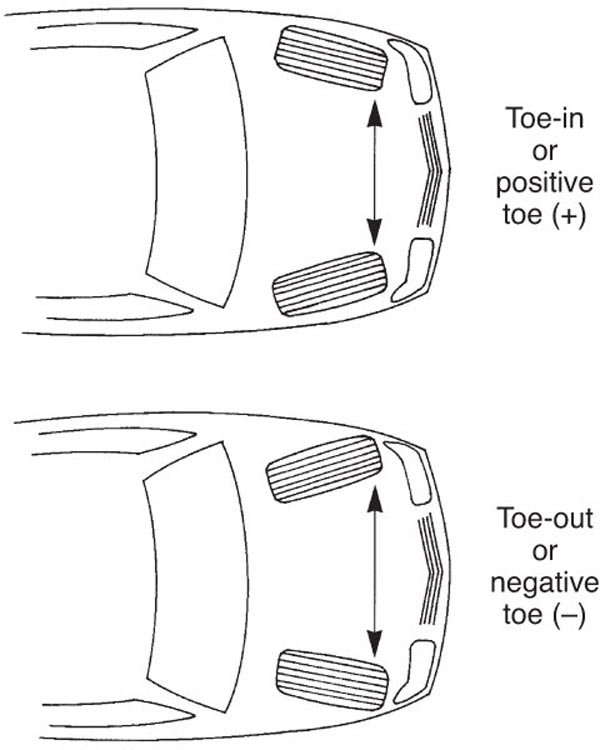

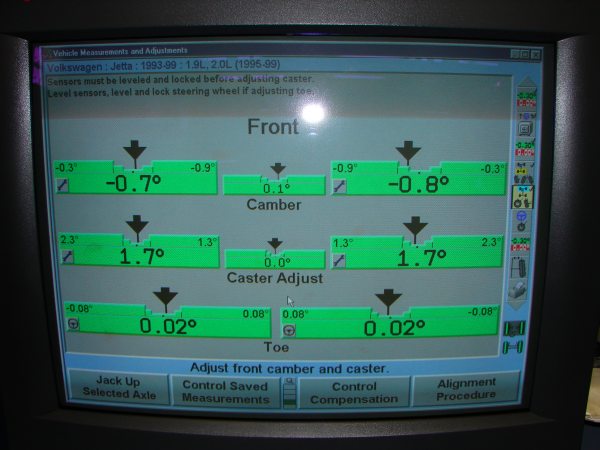

An alignment is highly recommended after this job.

Only toe is effected, but toe is the major player in eating tires, and crooked

steering wheels. If you do this job carefully, you can get the alignment

close, but its still going to be off. 2 degrees off may not sound like a

lot but it is a major tire wear issue. The MKIII model line wants to see a

toe "that is zero", meaning there should be NO toe in or toe out. The

tie-rods are the point at which all cars with a rack and pinion steering system

have the toe set at.

If there is fluid leaking out of the rack boots - don't

bother with new boots - you have bigger problems - fluid leaks at the rack boots

mean bad news - the rack seals are leaking, and you need to install a new rack.

Installation is not overly difficult, and can be done with

mostly hand tools, with two exceptions. One is a 32mm wrench. A

big-ass open-end 32 mm wrench is needed to remove the inner tie rods.

Another tool, that I prefer is a KD (tool company) 3312 (part number

KD-3312). This is a tie rod remover that slides over the inner rod, and

prevents a TON of hassle. By the book, VW says that the rack has to be

removed in order to get to the inner rods. While, sure, that's nice - its

a TON of extra work, steering column, sub-frame, rack mounts, power steering

lines would all have to come out - bah, we can do it in far less time.

IMHO the only thing this saves you at all is some hassle installing the rack

boots - and I'll show you a trick for that. This is a driveway job, once

your good at these, you can knock them out in 30 min a side. With the

right tools, ALL the work can be done from the wheel well! You don't even

have to really get under the car!

Parts Needed:

2 Inner Tie Rods

1 Left Outer Tie Rod

1 Right Outer Tie Rod

2 Rack Boots

4 1' long zip ties

2 new outer tie rod nuts

Tools Needed:

32mm Open End Wrench, OR KD tool # 3312

22mm Open End Wrench (two are handy to have)

13mm Open End Wrench

14mm Open End Wrench

17mm deep socket (1/2 drive)

19mm deep socket (3/8 or 1/2 drive)

BFH (Big F**king hammer - I prefer a nice well used 24-48 oz ball peen

hammer)

Torque Wrench that can go down to 25 ft lbs - and up to 81 ft lbs.

1/2" breaker bar. (Long handle)

Consumables:

PB Blaster/CRC Power Lube

Red Locktite

Razor blade.

|

Step 1 - Lift and support the car on

jack stands. Give the car a good shake to make sure its not going to fall

on you when your working on it.

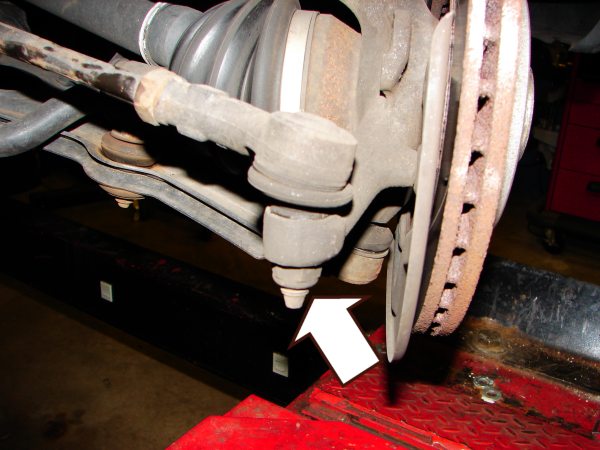

Get out your 19mm deep socket and go to town, take this

nut off. If the nut spins, and wont come off - chances are the out joint

is really worn. In that case try to spray the joint down with PB blaster/CRC

Power Lube, and wait 10 min. Then try it again. If your lucky hand

tools can remove it. If not try air power, or just cut the nut off.

You should have gotten a NEW nut when you got the new outer joint. There

is a 5mm(?) allen opening in the end of the joint - this is worthless, and will

strip out as you look at it. Another option is to cut a slot with a Dremel

in the bottom of the stud, and then hold it with a screw driver as you use an

open-end wrench to take the nut off.

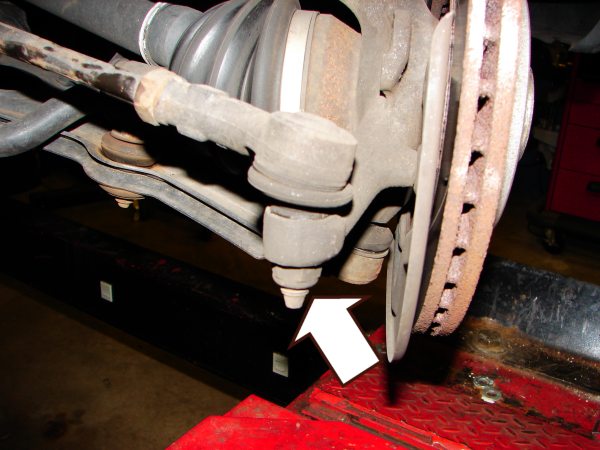

Step 2 - With the nut loose, (but still on the

threads) - hit the steering knuckle with a hammer. Yes, a hammer, and

you'll shock the tie rod free from the knuckle. Forget about hitting it on

the threads, that wont work, and if for some chance, you turn back now, you'll

have ruined the threads and wont be able to steer the car. Forget about

"pickle forks" and presses as well - they are all totally unnecessary. Hit

it hard, your not hugging grandmom. Swing away. 3-4 hits should

shock it free.

With some PB blaster again, soak down the 22mm jamb

nut on the inner rod. If you can, loosen it and then separate the two (the

inner from the outer). The inner tie rod is a 13mm, and there is a large

flat area on the head of the outer tie rod - that can take another 22mm open end

wrench.

Tech Tip! - Count the number of times you turn

the outer tie rod - in order to remove it - this will get the alignment "close"

to where it was before you took everything apart.

Step 3 - Well, I could not get the jamb nut off for

the life of me, so I just cut the inner rod - who cares, it was the cause of the

problem to begin with.

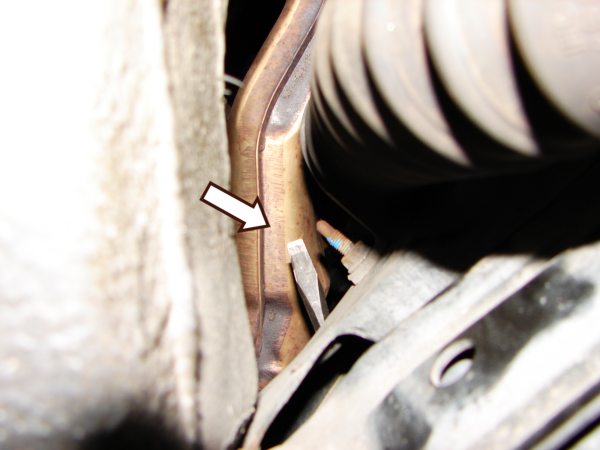

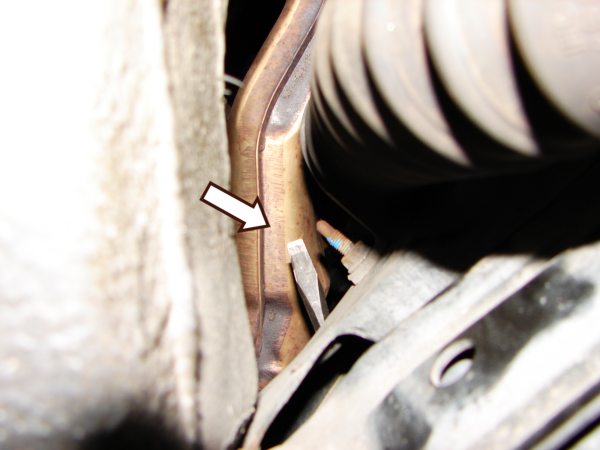

Step 4 - Off with the clamps. The OEM style

rack boots are held on with a metal clamp system that is identical to a CV joint

clamp. A special tool is used to install these clamps, and well, zip ties

work fine here... so pry, twist, cut (with wire cutters) off the old metal

clamps and chuck them. The picture below just shows you how you really

cant get to the clamps too well with a screwdriver from the direction shown.

I prefer to attack the clamps from the wheel wheel area of the car - I use a

long prybar and a hammer and just knock them loose. Forget about hurting

the boot, we got a new one.

And.. its off!

Be careful, they can be sharp and pokey.

Remember! If there is fluid leaking out

of the rack boots you have bigger problems - fluid leaks at the rack boots mean

bad news - the rack seals are leaking, and you need to install a new rack.

No over the counter "sealer" or other crud is going to help at all - get a new

rack, and use the OEM fluid!

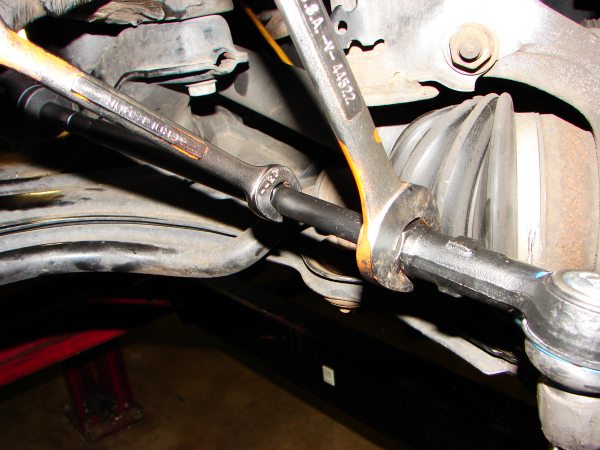

Step 5 - Yank off the boot and turn the steering

wheel so you can access the flats on the inner joint when your big ass 32mm open

end wrench can fit in-between the subframe and control arm. From here, you

can turn the joint off - but I hate this way. It takes too damn long.

I Prefer the KD 3312 tool.

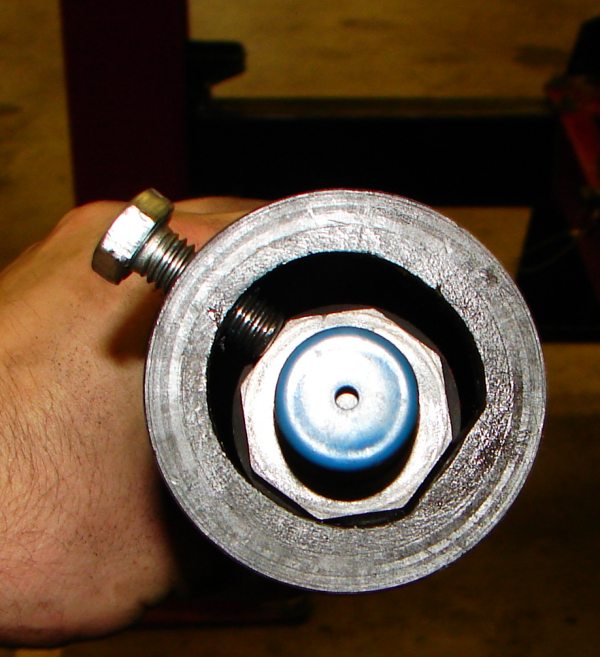

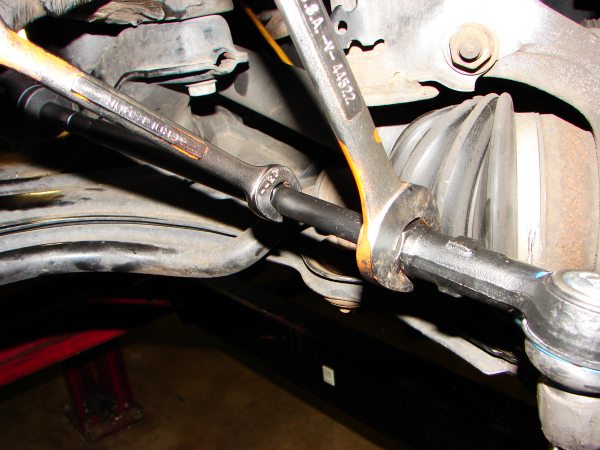

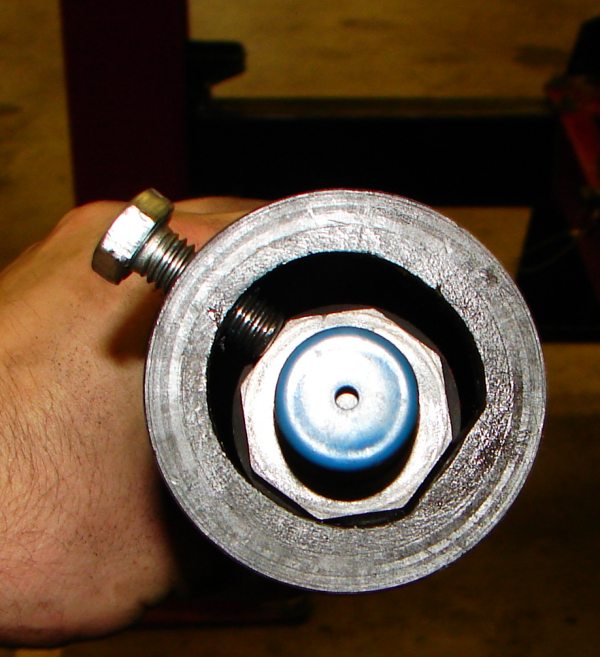

This handy unit shown below fits over the inner rod, and then has a 1/2" breaker

bar, ratchet, or torque wrench, and makes life as easy as cake.

The small bolt on the end holds the inner joint flat

(where the 32mm wrench would go) in a stable position so you can unbolt and bolt

in the new inner tie rod with just a few turns. Righty tighty-lefty loosey.

These are not reverse threads.

Install it as shown, and snug the bolt down with a 14mm

open end wrench.

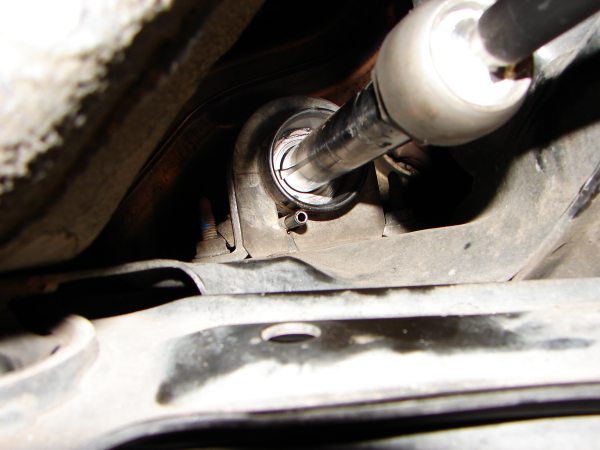

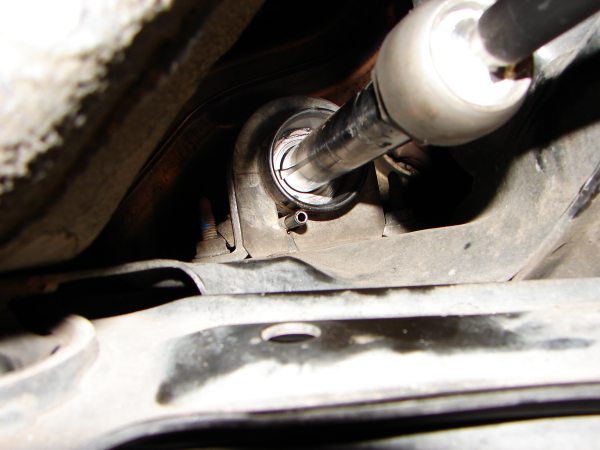

Step 6 - Done, The inner rod is removed, and

you can see it just has threads that hold it in place. No special locks or

seals are used here.

Getting the new boots ready - Note, there is a breather

hole, and cross over tube as part of the racks boot system. This breather

tube is needed since the rack is sealed from the outside. The rack

boots are like bellows and breath into each other. The cross over tube

allows air to flow in and out of each bellow and keeps the system sealed without

popping off the bellows. Getting the boots back on, can be a pain in the

ass - making sure they are fully seated, and lined up is the hardest part, but I

have some tricks.

Getting the boots on is critical to the life of the rack

seals. If dirt, water, rust, moisture or anything gets on the rack here -

you'll have major issues here. The rack seals will become damaged and then

you'll leak fluid out of the rack. And - that means you replace the rack.

Its that simple. So unless you feel like shelling out a ton of money, and

time, and doing the job again - make sure the rack boots are on right.

Paint with white paint, a line down the boot so you can

make a mental note of where the hole is.

And cut, a small slit on the INSIDE of the boot.

This will save you a long time of trial and error with your hands in a small

confined space with the control arms digging into you hands... The small

slit allows the breather tube to line up with the boot and just makes it a

thousand times easier and still keeps the system sealed and safe.

Step 7 - Install the new inner tie-rod. I prefer to

add a dab of red locktite on the threads of

the new inner rod where its going to mate to the rack. Carefully thread

the inner rod onto the rack, and then torque it down to 59 Ft Lbs.

THIS TORQUE IS CRITICAL! IF THE INNER JOINT COMES

LOOSE FROM THE RACK YOU WILL LOOSE STEERING CONTROL.

Note, just something interesting on the drivers side:

They are the rack teeth of the "Rack and pinion".

Don't worry, your supposed to see grease here, this is not a fluid leak!

Step 8 - Install and line up the new rack boot.

Install the new outer tie-rod onto the new inner one... counting the turns.

Don't forget the jamb nut goes onto the inner joint

BEFORE you install the outer joint!

Did you install the boot? Did you

install the jamb nut?

Did you?

Sure?

Go look again.

Step 9 - With all the parts lined up snug down the

jamb nut against the outer tie rod end.

Step 10 - Install a new zip tie to both ends of the

boot. Its tricky, but try to get them snug. Snip off the excess.

Install the lower outer tie-rod nut (the one we removed

in step 1), tighten that down to 26 ft lbs.

Reinstall the wheels and torque the wheel bolts to 81

ft lbs.

Review the

Pre-alignment tips.

Step 11 - Get a perfect alignment. And enjoy

a car that steers like new again!

Home

This

"how to" assumes you have some basic tools, and safety gear. Safety glasses

should be worn at all times when working with tools and automotive fluids.

Always use a hydraulic jack and safety stands when lifting or getting under a

vehicle. If you are unsure on where to safety lift your vehicle, refer to its

owners guide. Steering and Suspension components should never be heated with a

torch, bent, or welded. Replacement parts must be direct matches and should be

torqued to specification. The writer of this how to assumes zero liability

in how to use this guide, or any damages that may come from it to you, your

property, or others and others property. If you are uncertain at any point,

refer to a qualified automotive technician.

This

"how to" assumes you have some basic tools, and safety gear. Safety glasses

should be worn at all times when working with tools and automotive fluids.

Always use a hydraulic jack and safety stands when lifting or getting under a

vehicle. If you are unsure on where to safety lift your vehicle, refer to its

owners guide. Steering and Suspension components should never be heated with a

torch, bent, or welded. Replacement parts must be direct matches and should be

torqued to specification. The writer of this how to assumes zero liability

in how to use this guide, or any damages that may come from it to you, your

property, or others and others property. If you are uncertain at any point,

refer to a qualified automotive technician.