Going to the alignment shop.

1 - read

http://www.aa1car.com/library/wheel_alignment.htm

It seems there is a rash of misinformation that is causing some people to

spend unwanted time and money when they take their MKIII to a shop to have it

aligned.

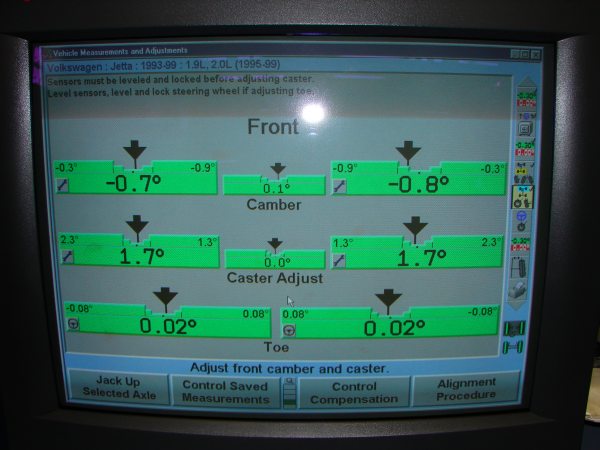

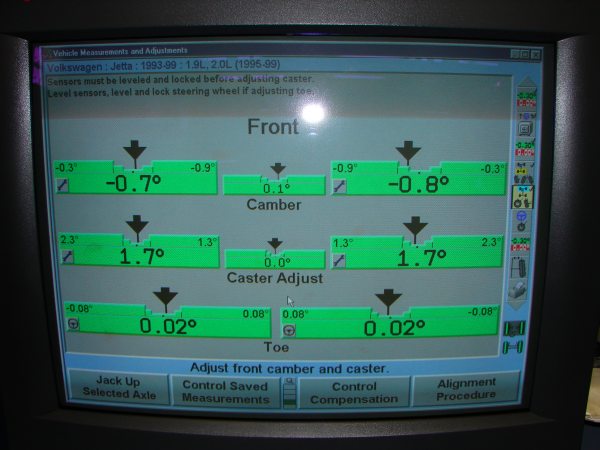

I’m not going to explain what the angles are that are involved, however I will explain what can and cannot be adjusted. Today I aligned my own car (myself) with a modern rack and computer setup (a Hunter R611 machine). And I thought I’d post a few tips and tricks to make your own alignment go smoother when you go to get it done. My car is lowered.

The following angles are EASILY adjustable, without special tools or kits.

Front Toe, and Front Camber.

These can be adjusted with basic hand tools. These are really the only two angles that most shops will even bother with.

“they said I need a camber adjusting kit” - You really don’t, - however it *does* make the job easier. If you are installing coils or a cup kit for the 1st time - I suggest you install a kit like this:

http://www.eurosportacc.com/camber.htm

SPC EZ Cam™ XR Camber Adjusting Bolts OR H&R Camber Adjusting Bolts

For under $40 you can’t go wrong and its going to make your life and the alignment tech’s life a ton easier. Install these BEFORE going to the shop!

What’s NOT easily adjustable; - With the exception of a “master frame” or body shop - where as the car has been in a major accident or collision.

Rear Toe and Camber - Front Caster.

Rear Toe and Camber are typically NOT adjustable, and CAN be adjusted

with using a special shim kit that shifts the position of the rear sub axles. If

the car has hit a curb, the stub axle (spindle) or beam can be bent. More often

then not the rear spindle is the cause of the issue. If replacing does not

correct the issue, the rear beam or shims must be installed to correct for the

change. Either one of these are rated “huge pain in the ass” by most shops and -

frankly don’t expect any $50 alignment to correct these issues at all.

Front Caster -

Is not adjustable - and is built into the car by the lower control arms. If

your car is lowered, or has been hit - forget about this angle - just forget

about it.

Got it? Good. Tell the guy. Say this. “I know I’m getting

a 4 wheel alignment, but don’t bother adjusting rear toe and camber, and front

caster. “ That right there, takes off a load of pressure.

Why a 4 wheel when I can only adjust the two fronts? - Because all 4 sensors are needed to make a proper alignment. In order to have the car track down the road right, it’s important. So, just pay for the 4 wheel.

And just when do you need an alignment?

After major suspension work (ball joints, struts, coils,

springs, tie-rods, control arms).

After a kissing a crub or brush, bick, or fents.

After a hit that was bad enough to bent a wheel.

After an accident.

Adjusting Ride Height will change camber and in turn, adjust toe.

WHEN YOU ARE ALL DONE YOU SHOULD GET A PRINT OUT! YOUR STEERING WHEEL SHOULD

BE LEVEL!

Before you go - Inspect and Replace

Check and replace any loose or damaged tie-rods, struts, ball joints, wheel

bearings, etc… if these are loose at all - AT ALL - your throwing your money

away when you get an alignment. Save yourself a ton of hassle by getting the car

solid before you go.

Loose Lips Sink Tips - Take your front lip off. Not only is it going to get

snagged on the rack - it may block the front toe sensors - making a lot of added

headache and hassle for the poor guy sweating under the car.

Winter Wheels - Put them on. Yea I know you got your coils all set. Put your ugly - care free wheels on the car. Mounting the wheel sensors can scratch a wheel if the guy slips up. Don’t worry as long as the final wheel/tire combo diameter is close to the same (say within 2”) you’ll be fine, come home and put the summer wheels back on the car.

Tires - Make sure your tires are OK - funky wear patterns will throw things off.

Commiserate and Communicate - Hey, the guy doing the alignment has a life too. If its hot out, offer to buy him a soda, if its cold in the shop - ask him if he wants a coffee. Seriously - a nice customer who does not hover while the guy is working will get a 110% job. Bitch with the guy about sports, the weather, other cars you both hate… its fun.

Lube it, Lube it real good - Wipe down the tie-rod

adjuster nuts with some PB Blaster a day or so before you go. Lube up the camber

adjusting bolts on the struts. - This will help stuff loosen up - better yet -

make sure YOU can work them loose - this will prevent the tech from bringing out

the smoke wrench. (That’s a torch…)

TP Check - Check and set tire pressure before you go - this saves them some

time.

Rear Beam - Its pretty much not adjustable - so if the tech says “Its out of spec, it needs to be replaced” - tell them “Well, do the best you can to get the thrust angle right.”. Again, that’s a long-term kind of job, and most shops don’t want the hassle of doing the work.

Dial In Your Ride Height - If your car has coils - set them up BEFORE you go - don’t expect the tech to mess with them at all - that’s not part of his job.

Timing is everything - Don’t rush out at 4 pm on a Hot July Friday after you put your suspension in and expect quick speedy perfect service. Its 4 pm on a hot summer Friday - the alignment tech is thinking of getting drunk and getting it on with his/her significant other. - Go in the morning, when its cooler out.. Is it snowing? Don’t go - no one wants snow dropped on them when working - doing alignments when it’s snowing out sucks so hard, I can’t even tell you.

Steer Straight - IF your steering wheel is OFF more then say 30 degrees - you should remove the airbag from the car, and reset the wheel. To do this:

Unhook the battery.

Center the wheel so the car is “driving straight” - but the wheel is crooked.

Make a mental note of the position.

Unbolt the airbag using a Allen key.

CAREFULLY move the bag out of the way, DO NOT PULL ON THE WIRES OR YANK THE BAG!

CAREFULLY PLACE THE BAG ON TOP OF THE WHEEL.

Using a 24mm socket. Loosen the center wheel nut. DO NOT REMOVE IT.

PULL HARD ON THE WHEEL TOWARDS YOURSELF TO BREAK IT FREE.

Then once its free remove the center nut fully.

CAREFULLY PULL THE WHEEL SO IT JUST CLEARS THE SPLINES! IF YOU PULL THE WHEEL

TOO FAR OUT YOU WILL DESTROY THE AIRBAG CLOCK SPRING! THIS IS A VERY

EXPENSIVE PART!

Rotate the wheel so its now centered, verify the airbag wires are not

misaligned.

Rebolt the wheel down to 40 ft lbs.

Reinstall the airbag. Snug the bolts down to about 10 ft lbs.

Hope this helps some out there.

WHEEL ALIGNMENT SPECIFICATIONS (Note OBDII cars are slightly different then 2,0 cars, same goes for the VR6 cars, but frankly the change is so small, its not a big deal at all..)

1993- 1995 2.0

Camber (1)

Front ................ -0.67 ............ -1 To -0.33

Rear ................. -1.5 .......... -1.67 To -1.33

Caster (Front) (1) .... 3.42 ............ 2.92 To 3.92

Toe-In (2)

Front ................ 0 (0) .......... -0.08 To 0.08

Rear .............. 0.17 (4) ........... 0.08 To 0.25

Toe-In (1)

Front .................. 0 ............ -0.17 To 0.17

Rear ................. 0.33 ............. 0.17 To 0.5

1996-99 1.9L

Camber (1)

Front .............. -0.5 .......... -0.83 To -0.17

Rear ............... -1.5 .......... -1.67 To -1.33

Caster (Front) (1) ... 1.75 ............ 1.25 To 2.25

Toe-In (2)

Front .............. 0 (0) .......... -0.08 To 0.08

Rear ............ 0.17 (4) ........... 0.08 To 0.25

Toe-In (1)

Front ................ 0 ............ -0.17 To 0.17

Rear ............... 0.33 ............. 0.17 To 0.5

1996-99 2.0L

Camber (1)

Front .............. -0.58 ......... -0.92 To -0.25

Rear ............... -1.5 .......... -1.67 To -1.33

Caster (Front) (1) ... 1.83 ............ 1.33 To 2.33

Toe-In (2)

Front .............. 0 (0) .......... -0.08 To 0.08

Rear ............ 0.17 (4) ........... 0.08 To 0.25

Toe-In (1)

Front ................ 0 ............ -0.17 To 0.17

Rear ............... 0.33 ............. 0.17 To 0.5

(all years) VR6- 2.8L

Camber (1)

Front .............. -0.5 .......... -0.83 To -0.17

Rear ............... -1.5 .......... -1.67 To -1.33

Caster (Front) (1) ... 3.27 ............ 2.77 To 3.37

Toe-In (2)

Front .............. 0 (0) .......... -0.08 To 0.08

Rear ............ 0.17 (4) ........... 0.08 To 0.25

Toe-In (1)

Front ................ 0 ............ -0.17 To 0.17

Rear ............... 0.33 ............. 0.17 To 0.5

(1) - Measurement is in degrees.

(2) - Measurement is in inches (mm).